Project Description

Case Study

Down to Earth

Head Product Designer

UX Designer

Content Creator

Sept-Dec 2020

How might we apply biomimicry to create textiles, processes or systems that enhance nature?

Following the RSA 2020 Design Brief, Material World, my team Meraki Inc. set out to create a startup business producing and selling 100% biodegradable underwear.

This was a 3 month project over my 4A term studying Global Business and Digital Arts at the University of Waterloo Stratford School of Interaction Design and Business.

Problem

Underwear has a short life span when used by its consumers, and a very long life span after use in landfills due to it being made from synthetic materials and harsh chemicals. This contributes to the growing global waste problem resulting in toxins seeping into our planet and bodies.

Role

I was the team lead behind this project focusing my efforts on product and UX design as well as content creation.

Skills

- Sprint Method

- Sewing

- Product Photography

- Layout

- Branding

- User Testing

- Figma

- Adobe Premiere Pro

- Mirro

Process

We used the Sprint method spending 2 weeks on each Understand, Diverge, Decide, Prototype, and Validate. As a team we produced video presentations encompassing the sprints work and our next steps moving forward.

Understanding

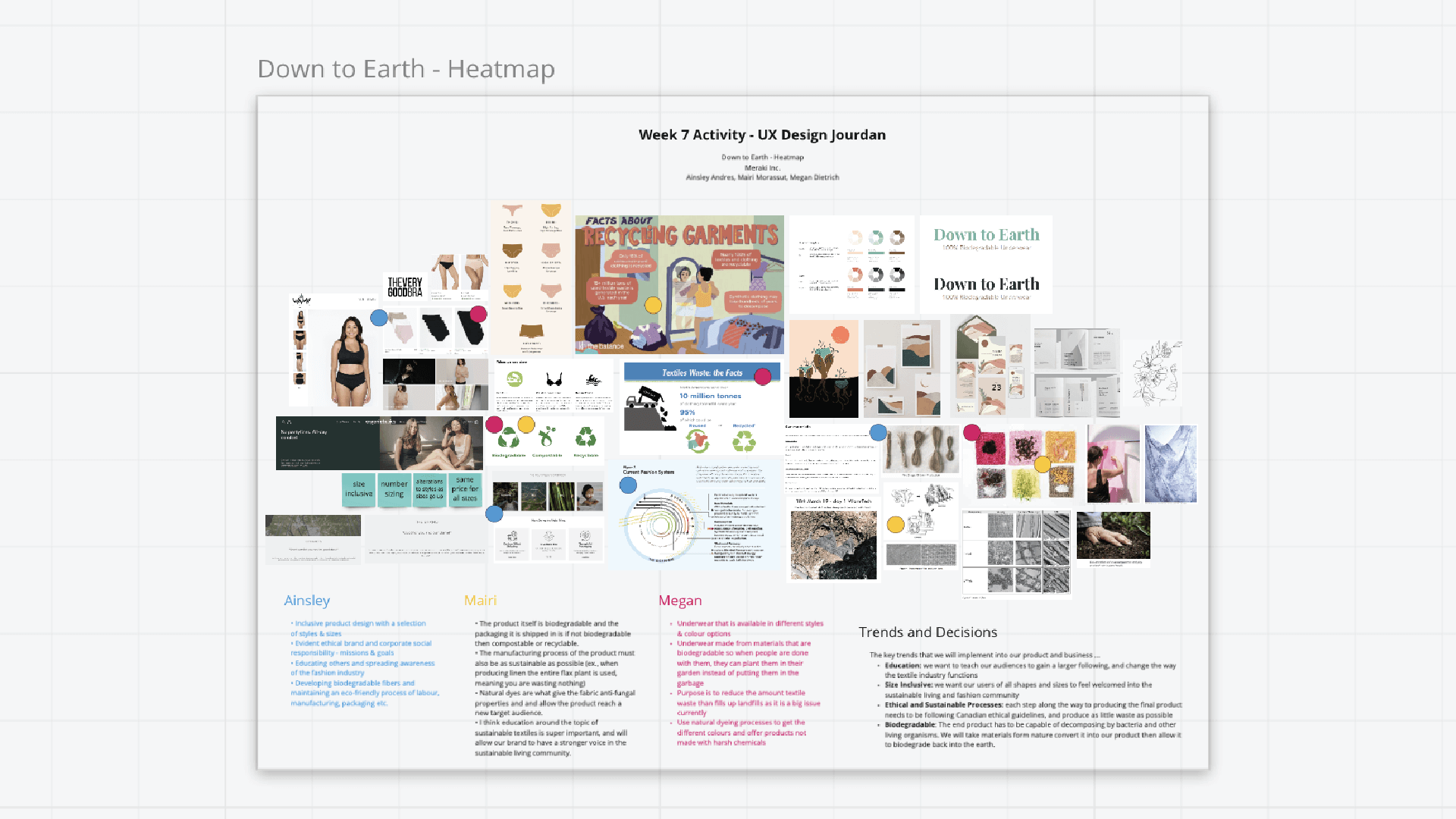

We created a survey and sent it out to our peers. We did a 360 Degree Review and Empathy Map as well. All to better understand the textile industry and user habits to seek out a niche problem in the textile industry that could be turned around with biomimicry.

Diverge

Individually we expanded ideas to proposed them to the team.

We created four personas with jobs to be done, pains, gains, and motivators for each.

Decide

As a team we narrowed down our target and converged into one idea to move forward with.

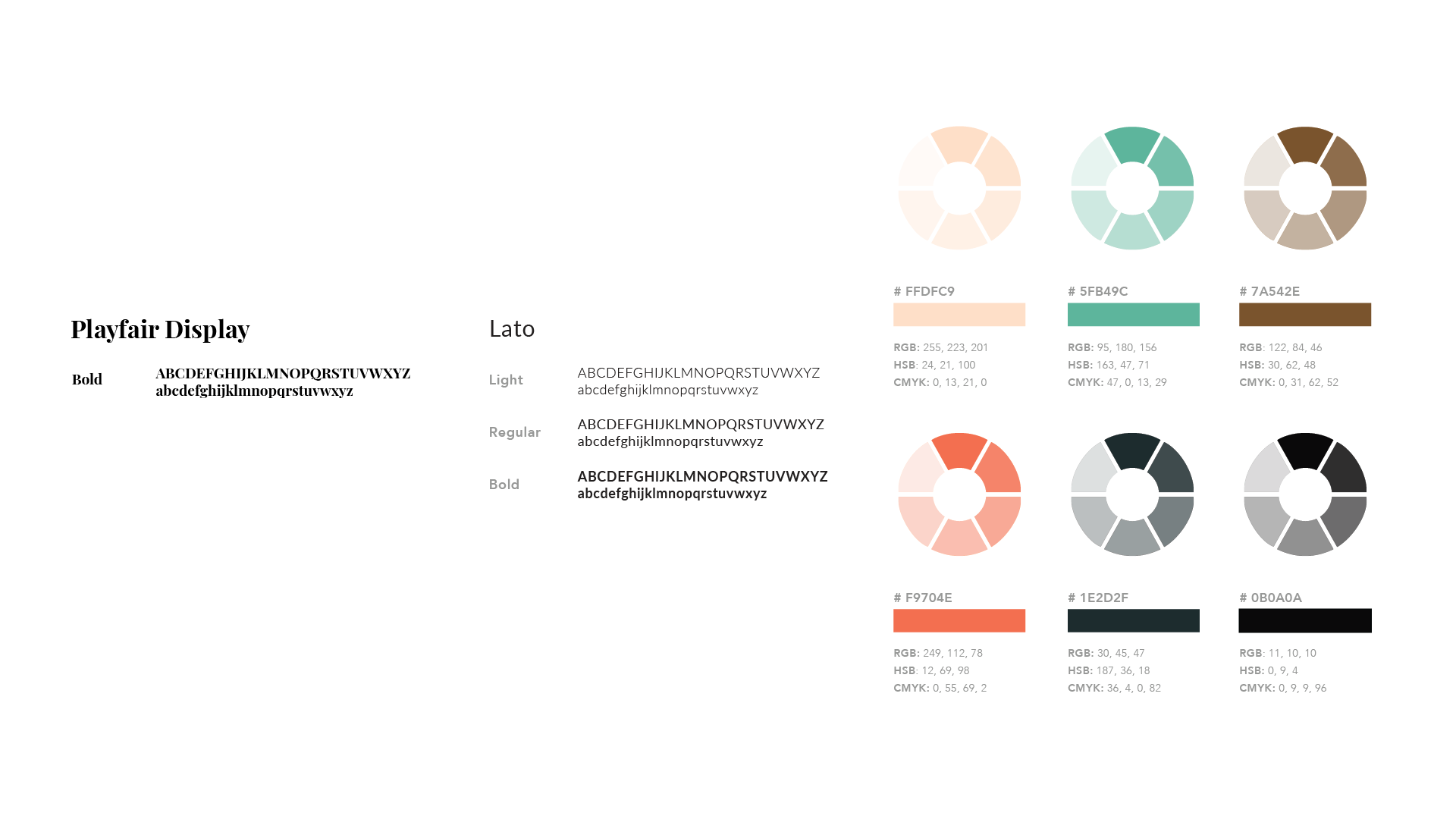

After the decision was made we created a mission, competitive product analysis and finalized branding style guide. We also created sory boards and product journey maps to visualize the users/customer journey with our brand.

Prototype

After shopping around for our prototype, we picked 100% natural cotton muslin and 100% cotton thread as our fabric textile. This type of woven cotton cloth was the only viable option. As for colours, we tested 8 different plant based dyes, to evaluate vibrancy, and distinguish which best matches our brand. I developed sewing and dyeing skills and gathered resources to produce a real product as our in house manufacturer. First, we washed 100% cotton muslin with plant based detergent to ensure the fabric is clean. While still wet, we let the fabric soak in a vinegar and salt water solution for 1 hour. This is to prep and set the fabric to better absorb and hold the colour. While that’s happening, water was boiled with cranberries. We chose cranberries to sample as our dye colour (based on its rich tones and extra antibacterial properties). Once the hour of wait time was over, we rinsed the fabric, removed cranberry remnants and placed the fabric in a pot. This boiled for an hour before removing heat and leaving fabric to sit. We ended with a rinse and left hanging to dry. The next day, we laid out the fabric and cut necessary pieces to make the first pair of sampled underwear. We sewed the pieces together using 100% cotton thread in different ways, using different techniques. With 4 different models of our product, we will be able to test and prioritize which characteristics work best to make any changes for a final product.

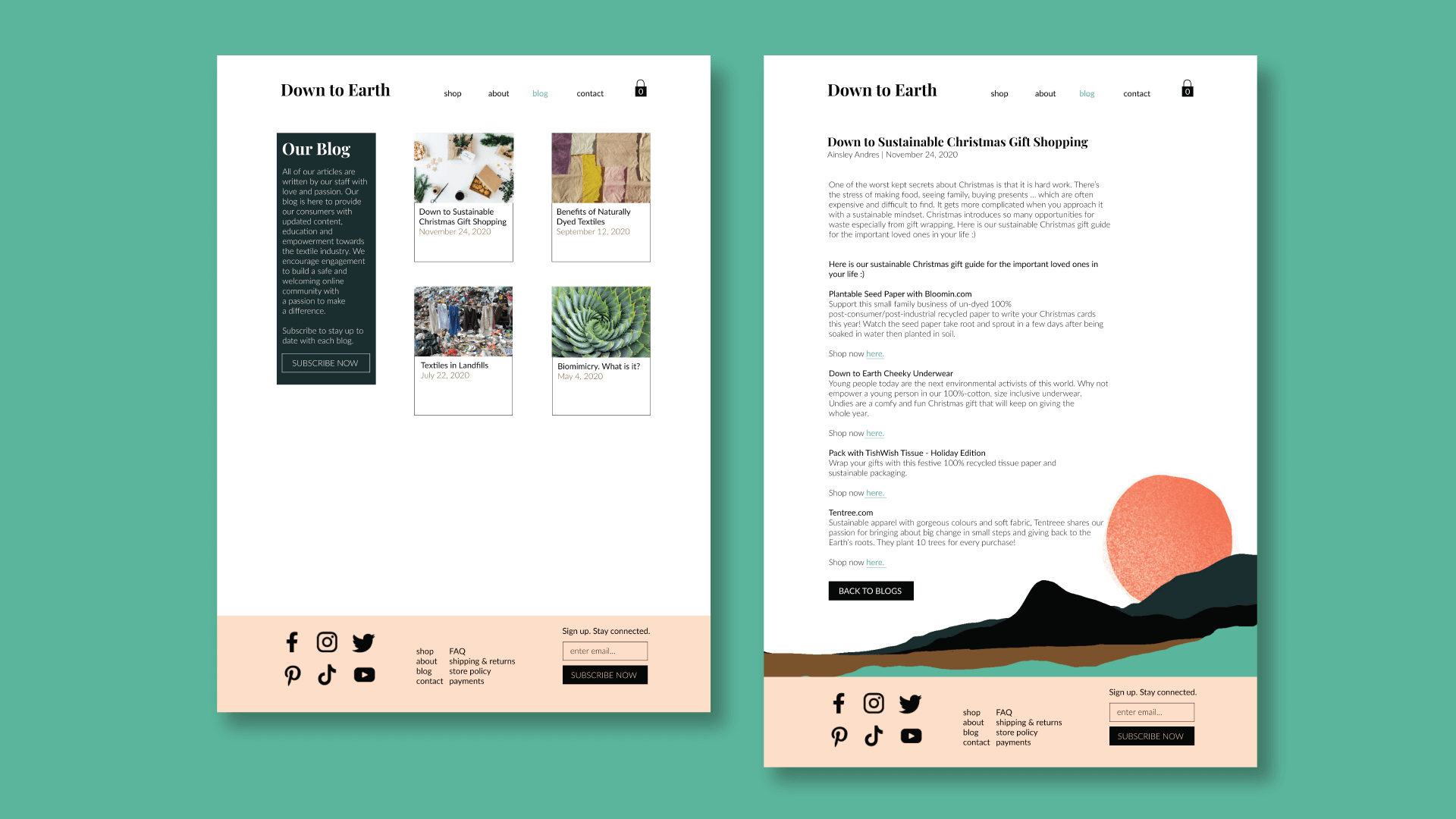

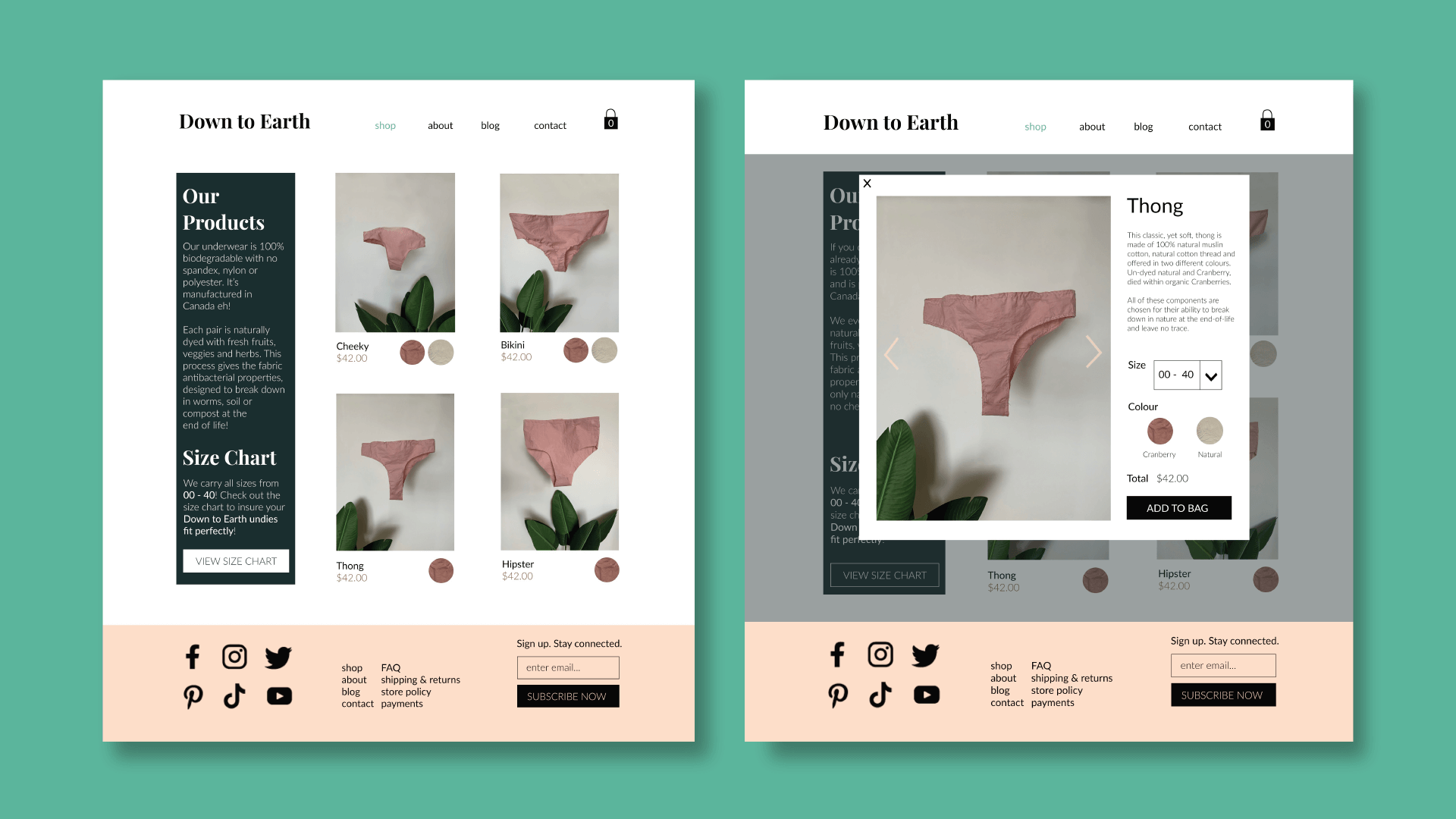

We also mapped out a web flow and created a wire frame to help us visualize the website skeleton and into real world simulations. I produced the high fidelity prototype in Figma, and animated them for user testing.

Click here to view live prototype website/online store

Validate

Through user testing we were able to seek out flaws in our prototypes both physical and digital. We conducted interview style user testing following a carefully designed series of questions and tasks to follow through our mockup. We asked our testers to speak their thoughts out loud and documented their feelings, thoughts and actions. Their feedback validated the need for our product and the user needs and desires for our proposed business.

To validate the physical underwear I performed 3 different tests. One being wash, where I washed different underwear samples using different methods and detergents. I performed a durability test rubbing the underwear fabric against its common companions, like denim, fleece, and polyester based pants. I also did a wrinkle test, scrunching up the fabric and leaving them in different environments. This was all to prove our products capability to sustain amongst your typical synthetic based underwear and suggest a care routine for our product.